HOW SPINNOMATIC WORKS

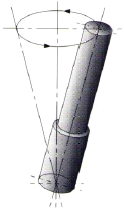

PRESSURE AND ORBITAL MOTION

The tool, held at a slight angle varying between 3° and 6° is brought to bear on the part. As the tool moves in an orbital path, a minute quantity of material (metal or plastic) is displaced with each rotation of the forming head until forming is complete. The actual forming tool (peen) does not spin, so problems with heat associated with friction are never a problem. The SpinnOmatic orbital forming machinery method forms a wide variety of metallic, non-metallic and plastic. The process is noiseless. The combination of pressure and motion form parts. Click here for benefits list & orbital forming process.

SPINNOMATIC FORMING HEADS

By changing the design of the forming tool (the peen), it is possible to change the shape of the finished head of the rivet. The table above shows some of the typical headforms, but our experienced staff in our development lab can design custom peens for any type of application.

Testing? Questions?

Send us your part print or come vist our lab to find the right peen for your next project.

Our Advantages

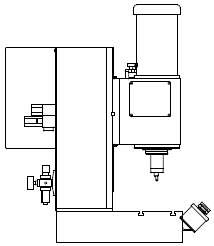

MODULAR DESIGN

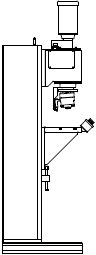

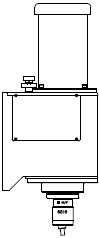

Our SpinnOmatic line of orbital fasteners are completely modular and can be used stand-alone or fitted on an automatic machine. Figure A shows the table mounted version for stand-alone operation. :Some of our larger SpinnOmatic fasteners are available in a pedestal mounted verson (Figure B) to deal with the higher forces used in the process. And Figure C shows the modular SpinnOmatic head. The modular head can be mounted to a column in and automated machine or assembly line.

FIGURE A

Table Mount

FIGURE B

Pedestal Mount

FIGURE C

Modular

M-40

M-50

How it Works?

eci SpinnOmatic™ Orbital Fastening combines pressure and orbital motion to accurately form or fasten parts, replacing the need for conventional riveting, staking, spinning, hammering, upsetting and welding. The SpinnOmatic is an orbital riveting machine, which keeps the peen stagnant- providing a frictionless experience.

INTEGRATION?

The SpinnOmatic design is easily integrated into automatic systems.

TRUST THE ORBITAL FORMING EXPERTS!

eci SpinnOmatic™ are world leaders in orbital forming and fasting technology and the industries leading producer of orbital forming machinery.

MISSION

Provide the industry with efficient, cost saving and time saving methods in all aspects of orbital forming and fastening, with an emphasis on positive customer service.